Increasing global energy demands and environmental concerns call for the development of energy conversion systems with high efficiency and minimal environmental impact. Fuel cells offer a promising solution due to their highly efficiency energy conversion process and low emissions profiles in comparison to fossil fuel combustion based-systems. In particular, combined heat and power fuel cell systems (CHP FCSs) are widely emerging as a reliable power source for a range of stationary applications. The research in particular was to examine different operational strategies in CHP FCSs, analyzing appropriate methods of thermal integration to ensure optimal performance in waste heat capture and recovery.

The research was conducted by Shuk Han Chan, Graduate Student Researcher at the University of California, Berkeley Transportation Research Center, in the Fuel Cell Laboratory at the University of Perugia, Italy under the direct guidance of Professor Umberto Desideri. Professor Desideri has a background in Mechanical Engineering as well as long-term expertise in energy conversion systems and renewable energy sources including fuel cells. He is the current director of The Energy Systems Group, a wide consortium of research facilities formed to support innovations and collaborations in the field of energy system through research, education and outreach.

High temperature proton exchange membrane (HTPEM) fuel cells and solid oxide fuel cells (SOFC) are of particular interest in CHP applications due to their point-of-use power generation ability on both small and large scale, high fuel-to-power conversion efficiency, low emissions, and the high quality waste heat produced. Within this framework, thermal integration of CHP FCSs with different thermal devices will be examined, including but not limited to afterburner (recovers heat and by-products from excess fuel and oxidant not consumed in the fuel cell), absorption/electrical chillers (provide cooling/heating loads to buildings), and air-to-air or air-to-liquid heat exchangers (for either space heating or water heating). Examination of different system design will provide valuable information for effective CHP FCS design and operational strategies.

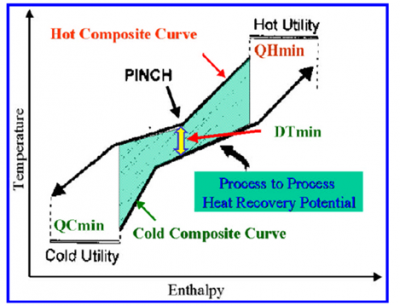

Pinch Point Analysis, a methodology based on thermodynamic analysis for minimizing the energy requirements of any process plants, was the procedure used in this research. The general principle behind this

technique is the optimization of waste heat recovery by minimizing the need to supply additional external cooling or heating. Pinch Point Analysis identifies the optimal process heat integration design where hot streams are used to heat cold ones and vice versa, with a minimum amount of additional heat transfer from an external source. Minimizing external transfer ultimately leads to both energy and cost savings.

The project takes on a whole system approach by addressing issues associated with the adoption of a green technology at all stages of its development including sustainable manufacturing, environmental concerns, health and society impacts, and technological challenges. The results of the assessment will help minimize impacts during the early stage of development. Ultimately, the use of a systems approach in the development of a sustainable technology such as fuel cells will serve as an important platform for identifying the most promising strategies for wide-scale implementation and technological advancement.